The manufacturing sector has seen a transformative shift with the rise of smart manufacturing. By integrating cutting-edge technologies like artificial intelligence (AI), the Internet of Things (IoT), and advanced analytics, modern industries are redefining efficiency, productivity, and sustainability. But what exactly makes smart manufacturing such a game-changer? Below, we’ll delve into the top benefits of smart manufacturing and how it is reshaping industries worldwide.

What is Smart Manufacturing?

Smart manufacturing refers to the use of advanced digital technologies to optimize production processes. These technologies include IoT sensors, machine learning algorithms, big data analytics, and automation systems. By embracing smart manufacturing, industries can make data-driven decisions, achieve real-time insights, and enhance operational agility.

In this new industrial paradigm, the focus shifts from reactive problem-solving to predictive and prescriptive approaches, enabling businesses to stay competitive in a rapidly evolving market.

Enhanced Operational Efficiency

Smart manufacturing enables companies to achieve unparalleled operational efficiency by automating repetitive tasks and reducing manual intervention. Automation minimizes human error, streamlines workflows, and optimizes machine performance.

With real-time monitoring and data-driven decision-making, businesses can also identify bottlenecks, predict maintenance needs, and address issues before they escalate. For instance, predictive maintenance tools powered by AI help prevent downtime, ensuring seamless operations and maximizing output.

Improved Product Quality

Quality control is a cornerstone of manufacturing, and smart systems take it to the next level. With sensors and advanced analytics, manufacturers can monitor production processes in real-time to ensure consistency and precision.

For example, IoT-enabled devices detect minute deviations in temperature, pressure, or other parameters, allowing for immediate adjustments. The result? Superior product quality, reduced defects, and increased customer satisfaction.

Cost Savings Across the Board

Smart manufacturing reduces costs in several ways, from optimizing energy consumption to minimizing material waste. Automated systems ensure efficient resource allocation, cutting down on excess inventory and energy usage.

Additionally, predictive analytics help industries forecast demand, plan procurement, and reduce overproduction. These cost-saving measures improve profitability and provide a competitive edge in cost-sensitive markets.

Data-Driven Decision Making

One of the most significant benefits of smart manufacturing is the ability to harness vast amounts of data for actionable insights. Advanced analytics tools process data from machines, supply chains, and customer feedback to optimize operations.

For instance, data visualization dashboards provide plant managers with a comprehensive view of production metrics, helping them make informed decisions. This level of insight improves agility and adaptability, essential traits in today’s dynamic business environment.

Increased Flexibility and Scalability

In the past, manufacturing processes were rigid, making it challenging to adapt to changing market demands. Smart manufacturing introduces flexibility by leveraging modular systems and digital tools that enable quick reconfiguration of production lines.

Industries can now scale operations up or down based on demand, launch new products faster, and customize offerings to meet specific customer needs. This agility fosters innovation and keeps businesses ahead of the curve.

Sustainability and Environmental Benefits

Sustainability is no longer a choice but a necessity. Smart manufacturing plays a crucial role in reducing environmental impact through energy-efficient systems and sustainable practices.

IoT sensors monitor energy usage in real time, enabling manufacturers to identify inefficiencies and implement corrective measures. Additionally, by reducing waste and improving recycling processes, industries can contribute to a circular economy, aligning with global sustainability goals.

Boosted Worker Safety

Safety is paramount in industrial environments, and smart manufacturing enhances it significantly. IoT-enabled devices monitor workplace conditions, detecting potential hazards such as gas leaks, high temperatures, or unsafe equipment.

Collaborative robots (cobots) also play a vital role by performing dangerous tasks, keeping workers out of harm’s way. Moreover, wearable technology like smart helmets provides workers with real-time safety alerts, ensuring a secure work environment.

Faster Time-to-Market

Time-to-market is a critical factor in today’s competitive landscape, and smart manufacturing accelerates this process. By integrating digital twins, manufacturers can simulate and optimize production processes before actual implementation.

This approach reduces trial-and-error, shortens design cycles, and ensures products reach the market faster without compromising quality. As a result, companies can respond quickly to consumer demands and capitalize on emerging opportunities.

Empowering Workforce with Advanced Skills

The shift to smart manufacturing demands a skilled workforce proficient in digital tools and technologies. While this might seem daunting initially, it opens up opportunities for upskilling and career advancement.

Employees trained in AI, IoT, and data analytics become valuable assets, driving innovation and ensuring the successful implementation of smart systems. Furthermore, automation takes over mundane tasks, allowing workers to focus on more strategic and creative responsibilities.

Integration of Supply Chain and Manufacturing

Smart manufacturing seamlessly integrates supply chain operations, enhancing visibility and collaboration. IoT-enabled devices track raw materials, inventory levels, and delivery schedules, ensuring smooth coordination between suppliers and manufacturers.

For example, blockchain technology enhances transparency by providing a tamper-proof record of transactions, fostering trust among stakeholders. This integration eliminates inefficiencies, reduces delays, and improves overall supply chain performance.

Greater Customization Capabilities

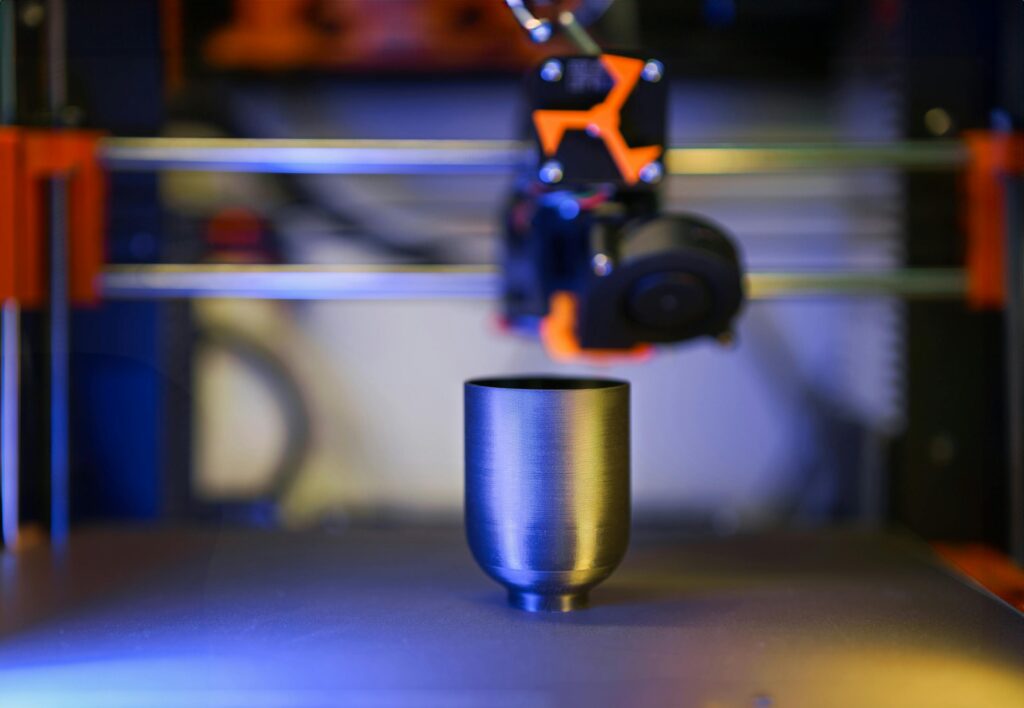

The modern consumer expects personalized products, and smart manufacturing makes customization feasible. By using additive manufacturing (3D printing) and flexible production systems, industries can tailor products to individual preferences.

For instance, automotive companies leverage smart technologies to offer customized features, colors, and designs, creating a unique experience for each customer. This level of personalization enhances brand loyalty and customer retention.

Remote Monitoring and Control

Remote capabilities are a hallmark of smart manufacturing. With IoT-enabled systems, managers can monitor and control production processes from anywhere in the world.

Cloud-based platforms provide real-time insights, enabling quick decision-making and issue resolution. This remote access not only boosts efficiency but also ensures business continuity during unforeseen circumstances, such as a global pandemic.

Enhanced Collaboration and Connectivity

Smart manufacturing fosters collaboration by connecting various departments, systems, and stakeholders through a unified digital ecosystem. This connectivity improves communication, accelerates decision-making, and enhances overall productivity.

For instance, enterprise resource planning (ERP) systems integrate data from procurement, production, and sales, ensuring all teams are on the same page. Such collaboration drives synergy and aligns efforts toward common goals.

FAQs

Smart manufacturing enhances productivity through automation, real-time monitoring, and predictive analytics, enabling faster, error-free production and optimized workflows.

Industries like automotive, aerospace, electronics, and pharmaceuticals benefit significantly due to the need for precision, scalability, and efficiency.

IoT connects machines, sensors, and systems, providing real-time data that helps optimize processes, monitor performance, and predict maintenance needs.

Yes, with scalable technologies and cloud-based solutions, even small businesses can adopt smart manufacturing to reduce costs and improve operations.

AI analyzes data, identifies patterns, and offers predictive insights, enabling manufacturers to enhance quality, efficiency, and decision-making.

Companies can start by investing in IoT devices, data analytics tools, and employee training, followed by gradual integration of advanced systems and automation.

Conclusion

Smart manufacturing is revolutionizing the industrial landscape, offering unparalleled benefits such as enhanced efficiency, cost savings, and sustainability. By embracing these advanced technologies, industries can future-proof their operations, adapt to market demands, and achieve long-term success.