Generative design offers a smarter, faster way to design components. You provide the requirements, and the software generates multiple solutions. Generative design uses artificial intelligence (AI) and cloud computing. As an engineer, this can revolutionize how you create mechanical components. It saves time and helps you reach the best possible design.

What is Generative Design?

Generative design involves AI-driven design exploration. You input key parameters: design goals, material constraints, manufacturing methods, and cost limitations. The software generates multiple options that meet those requirements. It evaluates design permutations while you select the most promising results.

Instead of manually iterating, you allow the AI to do the work. You maintain control and refine the options. This process saves effort and expands possibilities.

How Generative Design Works

Imagine designing a support bracket. First, you provide functional requirements: load conditions, attachment points, and preferred materials. Generative design software uses these inputs to create possible solutions. It evaluates designs based on parameters like strength, weight, and manufacturability. Within minutes, you get numerous options. Many of these designs are solutions you may not have considered before.

The advantage here is clear. The software approaches design without preconceived notions. It creates geometries that maximize performance and minimize material use. This innovation results in better mechanical components.

Benefits of Generative Design

Efficiency

Generative design saves you time. Automation reduces the iteration process. You can focus on testing and refining designs rather than spending hours manually creating each one.

Material Optimization

Generative design optimizes weight, strength, and material use. This optimization reduces waste and material costs. The lightweight designs are valuable, especially for aerospace and automotive industries.

Manufacturing Flexibility

Generative design considers manufacturability. You include manufacturing constraints like CNC milling or 3D printing. The software ensures that designs are feasible for production. This way, you avoid designs that are impractical to manufacture.

Innovative Geometries

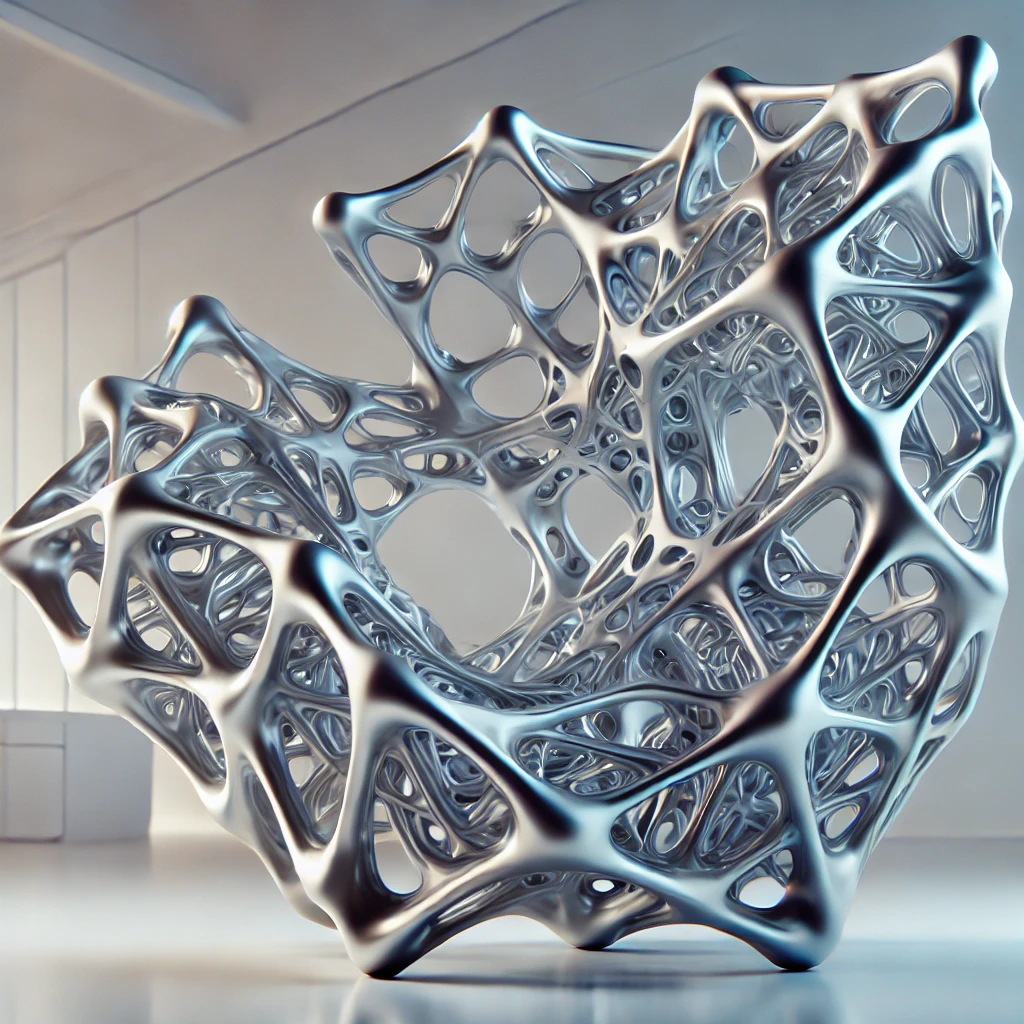

The design software often suggests organic, non-intuitive shapes. AI-optimized shapes outperform traditional blocky designs. You reduce stress concentrations while maximizing stiffness. Material is used only where needed, keeping weight to a minimum.

A Practical Example: Automotive Component Design

Consider designing a suspension control arm for a car. Normally, you might choose a simple, conventional geometry. But generative design enables a fresh approach. You input load cases, materials, and design constraints. The software suggests optimal geometries. These shapes may look skeletal and organic, but they serve an important purpose.

The skeletal structure maximizes stiffness while reducing low-stress material. You can assess whether the generated design can be cast, machined, or 3D printed. Generative design helps you reach practical solutions quickly. It narrows down design choices, saving you time and effort.

Key Phrase Focus: Generative Design

Generative design makes mechanical engineering efficient. Generative design optimizes materials and reduces waste. Generative design creates lightweight, strong components. Engineers gain manufacturing flexibility with generative design. Generative design generates innovative geometries. By using generative design, you save time and improve quality. Generative design offers advantages over traditional design processes. Start with generative design to explore component options. Generative design is revolutionizing mechanical engineering. Embrace generative design for better components.

Getting Started with Generative Design

If you want to try generative design, many software platforms offer this functionality. Autodesk Fusion 360, Siemens NX, and SolidWorks are great starting points. The learning curve is not steep. If you are comfortable with CAD, generative design adds another tool to your toolkit.

You can start with a non-critical component in your next project. Experiment with different goals and constraints. Observe how the software responds. Generative design offers ideas you might not consider alone. This leads to better component design in the long run.

Facts and Figures Table

| Aspect | Traditional Design | Generative Design |

|---|---|---|

| Iteration Time | Long | Short |

| Material Usage | Often Excessive | Optimized |

| Design Options | Limited | Many |

| Innovative Geometries | Few | Frequent |

| Efficiency Improvement | Moderate | High |

| Manufacturing Constraints | Manual Input | Automated Consideration |

Generative design outperforms traditional methods in efficiency, material usage, and optimization. It generates numerous design options quickly and considers manufacturing requirements automatically.

Final Thoughts on Generative Design

Generative design is transforming mechanical component design. It optimizes strength, weight, material efficiency, and manufacturability. You can explore an extensive solution space that leads to high-performing designs. Embracing generative design means embracing a smarter workflow.

By using generative design, you speed up the process. You get support from a powerful AI co-designer. This co-designer helps achieve optimal results. The future of mechanical engineering lies with generative design. Take the leap and explore generative design in your projects.

Generative design is ready to help you achieve your best designs. Let the AI assist your creativity, and see where generative design takes your work. Mechanical component design has entered a new era. Generative design is the future.